The M/V Isartal, a vessel measuring 88 meters in length and 13 meters in breadth, has entered our shipyard for a comprehensive repair and maintenance program. The scope of work includes extensive dry-docking operations, hull maintenance, steel renewal, and the replacement of selected piping systems and deck equipment.

As part of the scheduled works, our team is carrying out:

-

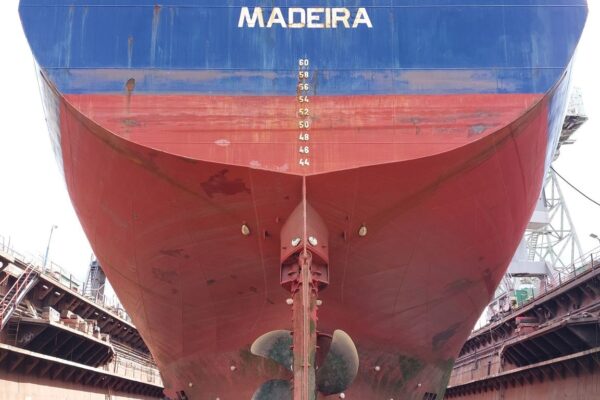

Dry-docking operations, including a full inspection of the vessel’s bottom and sides, cleaning, painting, and assessment of the hull’s technical condition.

-

Hull maintenance, involving surface cleaning, anti-corrosion protection, and the application of a new coating system to ensure long-term durability and improved operational efficiency.

-

Renewal of approximately 40 tons of steel, covering repairs to the hull structure and deck areas. All steel works are performed in accordance with the highest quality and safety standards.

-

Replacement and modernization of piping systems and deck equipment, improving the vessel’s reliability and compliance with current technical and operational requirements.

The main objective of this project is to restore the vessel’s full technical readiness while enhancing its durability and safety in operation. The ongoing overhaul of the M/V Isartal once again demonstrates the trust shipowners place in our shipyard’s expertise in high-quality repair and modernization services.